Mike Corbin, one of Hollister’s best-known business owners who has been a household name in the motorcycle world for decades, recently introduced his “proof of concept” prototype for a magnetically powered motor that he thinks will revolutionize the electric vehicle industry.

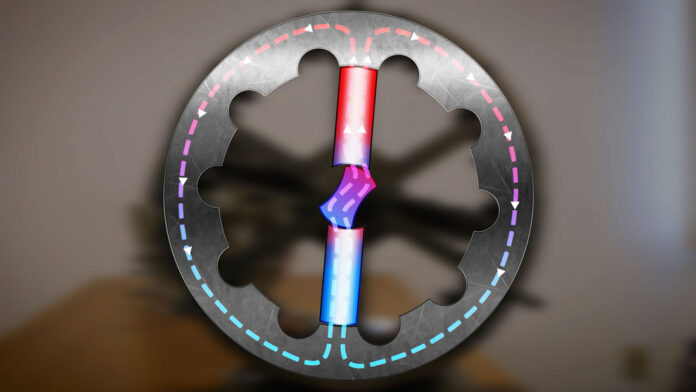

Known as the Corbin Motoflux Principle, Corbin secured a U.S. patent for the motor a couple years ago. The Motoflux principle uses a three-component design that incorporates a radial director that distorts the magnetic lines of flux in the armature, Corbin explained in a series of videos he rolled out this week for Motoflux’s public reveal. As the flux lines seek to shorten and tighten, the armature is drawn forward to the next closest pole tip of the stator. As a result, the Motoflux device has shown a torque output increase of four to 25 times more than input.

These gains, Corbin explains, are produced solely from the power of the permanent magnets inside the Motoflux motor.

“(We) want to extract power from the force stored in permanent magnets,” Corbin said. “The Motoflux principle gives us a way to get a magnetic field to rotate and give us torque.”

Motoflux has the potential to become the industry standard for clean-energy travel, Corbin said. The Motoflux motor consumes a fraction of the power that most commercial electric vehicle motors require, and thus needs very little energy storage, Corbin explained.

With more than two million electric vehicles already on the road in the U.S., and sales growing every day, the potential environmental impact of Motoflux is “enormous,” Corbin said.

“This is the most important thing that’s happened to rotating motors in the last 200 years,” Corbin told this newspaper. “This could take us beyond the electric car. (It runs on) permanent magnets and you don’t need batteries. It could solve all the problems with lithium ion batteries,” such as the expensive costs and the impact of mining limited natural resources required to produce such batteries.

Now that the concept is proven, Corbin is trying to get electric motor and vehicle manufacturers interested in Motoflux. The system can easily be incorporated into commercial and mainstream products, he said. The design is scalable and can be adapted for specific uses depending on manufacturers’ and developers’ needs.

Corbin, of course, is known best in Hollister for bringing his company, Corbin Motorcycle Seats & Accessories, to Technology Parkway in 1998. Having started producing motorcycle seats commercially in 1968, Corbin relocated the rapidly growing enterprise from Castroville to its current 82,000-square-foot headquarters in Hollister out of a need for more space to create seats that are delivered all over the world.

Corbin is also known locally for leading the revival of the historic Hollister Motorcycle Rally. Founded in 1947, the Independence Day rally had been on hold for a few years by the 1990s. Corbin and his son started lobbying the Hollister City Council in 1995 to bring the rally back for its 50th anniversary.

But Corbin has also been an electric vehicle proponent, creator and developer for decades. Several years ago, his company designed, manufactured and sold the three-wheeled Sparrow electric car. With a compact design and built for a single passenger, the Sparrow caters to commuters.

Corbin said he had the idea for the Motoflux principle in the 1970s, but “I never really got it working,” he said.

Over the last four years, Corbin has been working on building the Motoflux prototype at his company’s Hollister headquarters. He said in one of the Motoflux introductory videos that he built an early model in his garage at his home. “All great ideas come from somebody’s garage,” he quipped.

Locally, Motoflux could result in more jobs and more tax revenues coming out of Corbin headquarters if the concept takes off commercially. Corbin said Motoflux will likely generate a research & development arm at Corbin, employing a host of engineers and designers.

“The next best idea is coming out of America,” Corbin said.

Fantastic: I knew it could be done. Been working on this concept myself for 30 + years. This is simpler. Mine would require a polarity switcher integrated into a matching adjustable cone laden + & – . Been fascinated for years with this technology. This is salvation. Massive torque can be generated with super sized permanent magnets . All in a small package. Requires no fuel. Saver precious recourses. AND no pollution. Did i mention quite. I want to see one installed in a truck tractor trailer. No gears to shift. etc. LS

A friend invented an engine with magnets in the pistons to increase the power. He died and left me all his schematics, photos and lab notebooks. I’m trying to find a couple of universities to send the digital files to. He just wants somebody to take the idea and run with it. He put the prototype in a station wagon and drove it around San Diego in the 1980s. He used to work at JPL but invented this after he retired. If you are with a university, please send an email to Be******************@***il.com

Post it to many public forums of like minded people someone will run with it, Universities are shills for big corporations.

An EXCELLENT CONCEPT. Hurrah for our small town genius.